Abrasive Cleaners

Abrasive cleaners for belt and disc sanders play a critical role in maintaining the efficiency and longevity of these essential woodworking tools. They effectively remove built-up residue, dust, and debris from sanding belts and discs, thereby preventing clogging and heat buildup which can lead to reduced performance and potential hazards. Routine use of abrasive cleaners not only enhances the sander’s lifespan but also enhances the quality of woodwork produced, making it an indispensable practice for any woodworking classroom.

As educators, it is essential to emphasize the importance of regular cleaning and maintenance to ensure optimal performance and safety. By incorporating proper cleaning practices into woodworking lessons, educators can instill in their students a sense of responsibility for equipment care, fostering a safe and productive learning environment.

Sandblasting

Sandblasting cabinets serve to efficiently clean, strip, and finish surfaces by propelling abrasive materials at high velocity. Common abrasive media include aluminum oxide, garnet, and silicon carbide, each offering specific benefits based on the application. Bead materials, such as glass beads and ceramic beads, are also commonly used for more delicate surface treatments.

These cabinets are essential tools used in various industries, and as educators, it is vital to impart knowledge about their function and the types of abrasive media and bead materials they employ. Educators should stress the importance of understanding the characteristics of different abrasives and beads, as this knowledge empowers students to choose the appropriate materials for specific tasks while ensuring safety and maximizing efficiency. Proper training in handling sandblasting cabinets and their associated media will foster skilled and responsible technicians in various industries.

Sanding Materials

As educators, it is essential to familiarize ourselves and our students with the array of sanding tools available for various applications in woodworking and other crafts. They all play crucial roles in achieving smooth and precise surfaces.

-

Sanding belts are versatile, ideal for large surfaces and rapid material removal.

-

Sanding blocks, pads, and sponges offer flexibility and control, ensuring consistent results on curved or contoured surfaces.

-

Sanding discs are widely used on power sanders for quick and efficient sanding.

-

Sanding drums and sleeves are perfect for precise sanding in intricate areas.

-

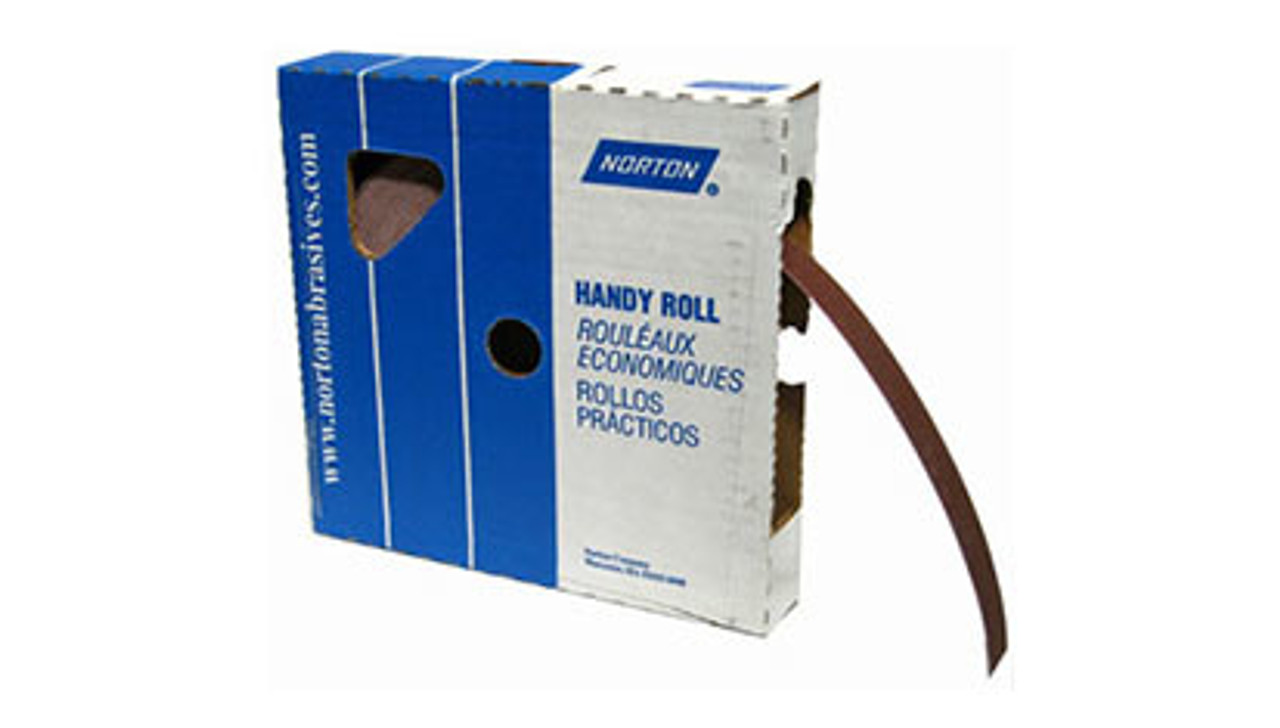

Sanding rolls provide cost-effective solutions for custom-sized pieces.

-

Sanding sheets are suitable for hand sanding or use with sanding blocks.

By understanding the distinct advantages and applications of these sanding tools, educators can empower their students to make informed decisions and hone their craft with precision and efficiency.

Sharpening Stones

Sharpening stones are a fundamental tool in the realm of bladesmithing and woodworking. They come in various materials such as natural novaculite, synthetic aluminum oxide, or silicon carbide. They play a vital role in maintaining the keen edge of knives, chisels, and other cutting implements.

As educators, it is crucial to impart knowledge about sharpening stones. Be sure to emphasize the significance of selecting the appropriate grit size for the task at hand, as finer grits yield sharper edges while coarser ones are better suited for initial sharpening or reshaping. Proper technique and regular maintenance of sharpening stones ensure precision and longevity of cutting tools, instilling in students the value of craftsmanship and attention to detail.